Popular Categories

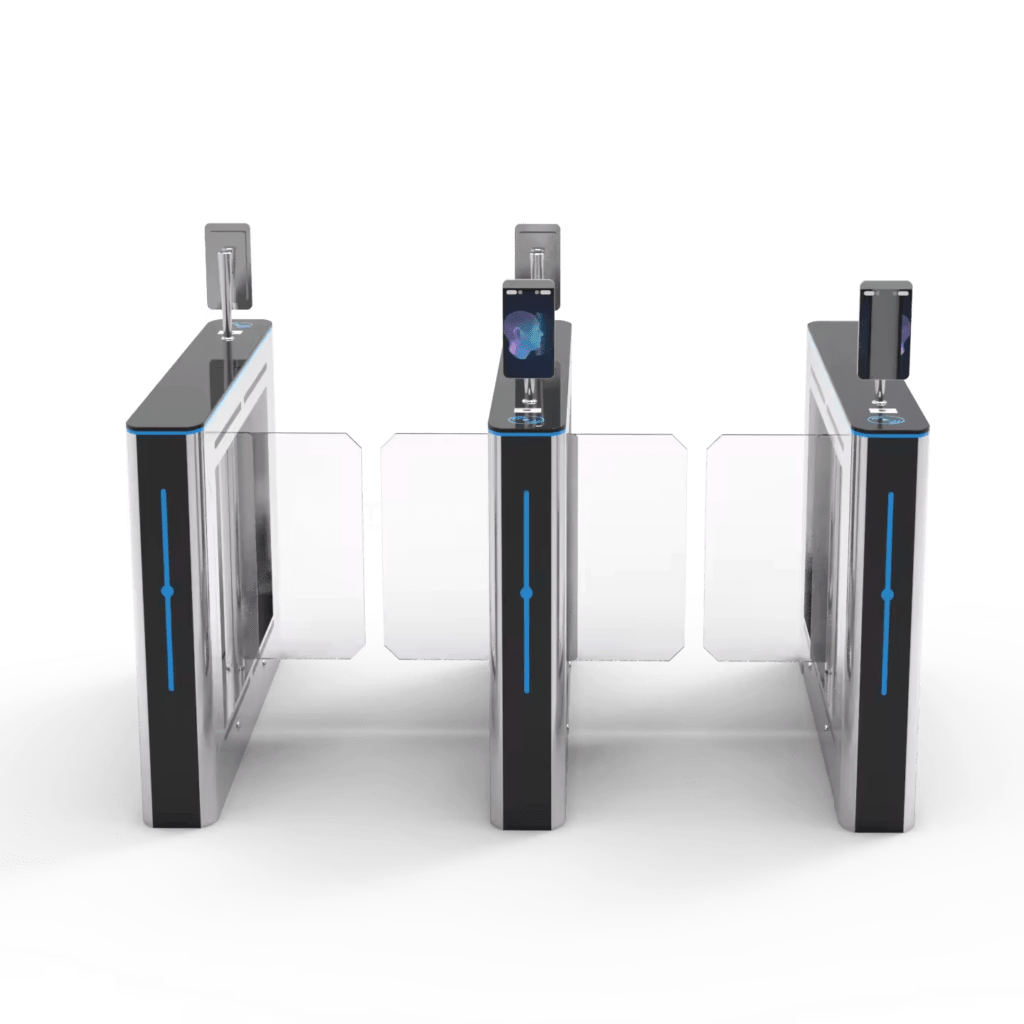

The Best Offers Boom Barrier

Hurry and get discounts on all Operator up to 5% - 20%

0

days

00

hr

00

min

00

sc

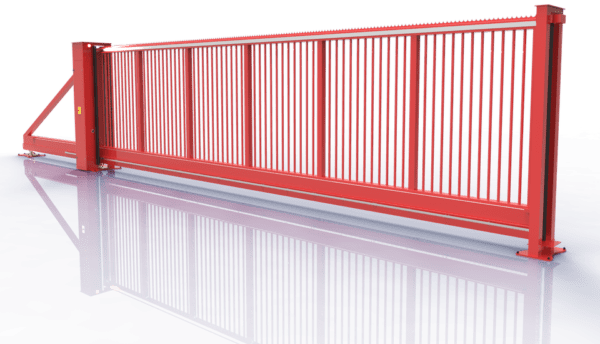

SS 304 Laser Cut Sliding Gate

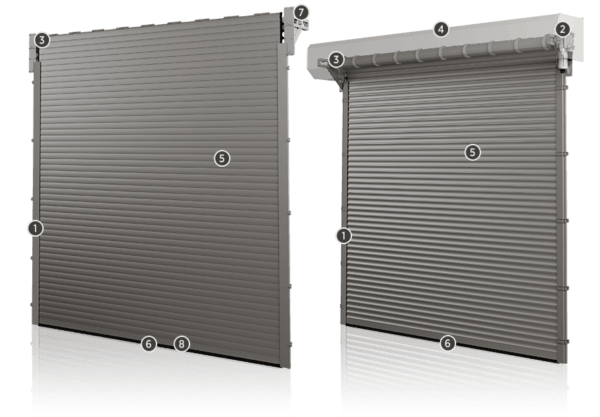

₹227,500.00UNITIndustrial Fabric Roll Up Doors

₹249,847.00Accessories Door RFID Card Control System MR-RFIDC1

₹1,800.00PICESEBluetooth Mobile App Remote Controller for Shutter Motor

₹4,277.00UnitAluminum Sectional Mirror Glass Garage Door

₹206,728.00SETSResidential Rolling Shutter Motor 300kg

₹16,520.00Kit